Laser Marked Sustainability In Pharma Packaging: The Role Of Laser-marked Canisters Technology

It addresses critical concerns such as contamination, product integrity, and traceability while supporting global sustainability goals

Byline: Manish Jain, Managing Director & Founder of Cilicant

As product safety, traceability, and environmental responsibility become critical priorities, laser-marked canister technology has emerged as a transformative solution in modern packaging systems. From pharmaceuticals and diagnostics to food, nutraceuticals, and industrial applications, this technology provides a cleaner, more secure alternative to traditional labeling and printing methods. It addresses critical concerns such as contamination, product integrity, and traceability while supporting global sustainability goals.

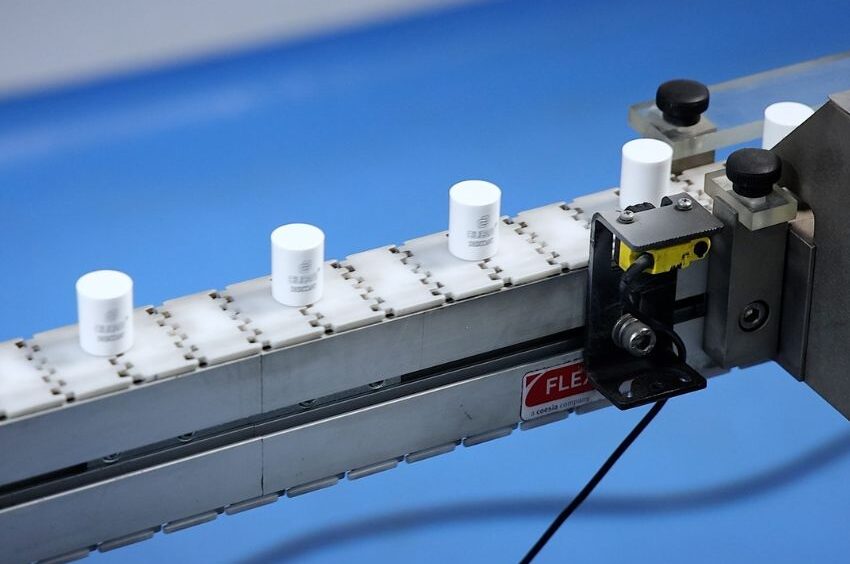

Laser-marked desiccant canisters are an excellent example of how advanced marking techniques can be seamlessly integrated into the packaging system. These canisters not only absorb moisture to protect product quality but also carry essential product information, permanently marked without the use of inks, labels, or adhesives.

What is Laser Marking Technology?

Laser marking is a precise, high-intensity technique that uses a focused laser beam to engrave or etch information directly onto the surface of a material. Unlike traditional printing methods, laser marking doesn’t rely on inks, dyes, adhesives, or paper. Instead, it modifies the surface itself to create sharp, permanent, and tamper-evident markings. This makes it particularly valuable in pharmaceutical and other sensitive applications where clarity, durability, and hygiene are of utmost importance.

Why Laser Marked Canisters?

Desiccant canisters are commonly used in packaging to control moisture and protect sensitive formulations from degradation. Traditionally, these canisters might carry information via labels or ink-based methods, both of which pose challenges in terms of durability and contamination. Laser marking effectively addresses these issues by providing a cleaner, more durable, and secure method.

Key features and benefits:

Precision and Clarity

Laser printing technology ensures that all markings are produced with exceptional clarity. The clean and sharp visual output enhances both functionality and brand professionalism. This precision improves traceability throughout the supply chain.

Durability and Longevity

One of the most compelling benefits of laser-marked canisters is the long-lasting nature of the markings. They are resistant to smudging, fading even under harsh environmental conditions like humidity, high temperatures, or prolonged storage. This ensures that critical information remains legible throughout the product lifecycle, which is essential for regulatory audits, recall management, and inventory control.

Mitigated Risk of Contamination

By eliminating the need for inks, labels, adhesives, or paper, laser marking significantly reduces the risk of introducing contaminants into packaging environments. This results in a cleaner, safer internal packaging environment, especially important for products sensitive to impurities, such as pharmaceuticals and food supplements.

Lower Environmental Impact

Laser marking contributes to sustainability goals by minimizing waste and reducing reliance on consumable materials. The elimination of inks, paper, and adhesive labels not only cuts down on resource use but also simplifies logistics by removing the need for storage and disposal of these materials. Additionally, the process helps lower the carbon footprint associated with traditional printing supply chains.

Tamper-evident Security

Laser marking enhances product security by creating indelible, tamper-evident information directly on the packaging component. Any attempt to alter or remove the marking results in visible damage, making tampering immediately noticeable. This feature is particularly critical for high-value or sensitive products, acting as a deterrent to counterfeiting and unauthorized manipulation.

Enhanced Traceability and Compliance

Laser marking allows for the inclusion of machine-readable data, such as QR codes or Data Matrix codes, which can be scanned at various checkpoints in the supply chain. This enables real-time tracking, supports inventory management, and aids in efficient recall processes. The ability to maintain a consistent, tamper-proof record of a product’s journey enhances supply chain visibility and regulatory compliance with global standards.

Laser Marking & Desiccant Canister

The desiccant canisters are designed to protect products from moisture, and laser marking enables traceable, long-lasting marking without compromising the canister’s function or introducing any contaminants. Even when concealed within a sealed bottle or exposed to challenging conditions, laser-marked data remains intact. This ensures continued traceability and authentication without requiring external labeling, making it a reliable choice for industries where stringent hygiene standards are in place.

Laser-marked canister technology offers a strong foundation for improving supply chain transparency and efficiency. This builds consumer trust, simplifies audits, and reduces the time and cost associated with compliance. Because laser marks are resistant to tampering or removal, they serve as a reliable source of truth in verifying a product’s authenticity. This not only improves operational efficiency but also enhances brand protection.

In today’s tightly regulated and highly competitive manufacturing landscape, companies must adopt technologies that not only meet functional and safety needs but also align with broader environmental and compliance objectives. Laser Marked Canister Technology does exactly that.

It combines high precision, robust durability, and environmental responsibility with practical benefits like improved traceability, reduced contamination risks, and enhanced product security. As packaging continues to evolve toward smarter, safer, and more sustainable solutions, laser marking stands out as a key enabler of quality and innovation across industries.

Whether used in pharmaceuticals, diagnostics, food, or other sensitive applications, laser marked canisters represent a forward-thinking approach to packaging one that protects products, supports compliance, and builds trust from production to end use.

The views expressed in this article are those of the author and do not necessarily reflect the views of the publication